<<–2/”>a >h3>Polyvinyl chloride

What is Polyvinyl Chloride (PVC), and What is it Used For?

Polyvinyl Chloride (PVC) is one of the most commonly used thermoplastic polymers in the world (next to only a few more widely used plastics like PET and PP). It is a naturally white and very brittle (prior to the additions of plasticizers) plastic. PVC has been around longer than most plastics having been first synthesized in 1872 and commercially produced by B.F. Goodrich Company in the 1920s. By comparison, many other common plastics were first synthesized and became commercially viable only in the the 1940s and 1950s. It is used most commonly in the construction Industry but is also used for signs, healthcare applications, and as a fiber for clothing.

PVC is produced in two general forms, first as a rigid or unplasticized polymer (RPVC or uPVC), and second as a flexible plastic. Flexible, plasticized or regular PVC is softer and more amenable to bending than uPVC due to the addition of plasticizers like phthalates (e.g. diisononyl phthalate or DINP). Flexible PVC is commonly used in construction as insulation on electrical wires or in flooring for homes, hospitals, schools, and other areas where a sterile Environment is a priority, and in some cases as a replacement for rubber. Rigid PVC is also used in construction as pipe for plumbing and for siding which is commonly referred to by the term “vinyl” in the United States. PVC pipe is often referred to by its “schedule” (e.g. Schedule 40 or Schedule 80). Major differences between the schedules include things like wall thickness, pressure rating, and color.

Some of PVC plastic’s most important characteristics include its relatively low price, its resistance to Environmental Degradation (as well as to chemicals and alkalies), high hardness, and outstanding tensile strength for a plastic in the case of rigid PVC. It is widely available, commonly used and easily recyclable (categorized by resin identification code “3”).

What are the Characteristics of Polyvinyl Chloride (PVC)?

Some of the most significant properties of Polyvinyl Chloride (PVC) are:

- Density: PVC is very dense compared to most plastics (specific gravity around 1.4)

- Economics: PVC is readily available and cheap.

- Hardness: Rigid PVC is very hard.

- Strength: Rigid PVC has extremely good tensile strength.

Polyvinyl Chloride is a “thermoplastic” (as opposed to “thermoset”) material which has to do with the way the plastic responds to heat. Thermoplastic materials become liquid at their melting point (a range for PVC between the very low 100 degrees Celsius and higher values like 260 degrees Celsius depending on the additives). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics like polypropylene liquefy, which allows them to be easily injection molded and then subsequently recycled. By contrast, thermoset plastics can only be heated once (typically during the injection molding process). The first heating causes thermoset materials to set (similar to a 2-part epoxy) resulting in a chemical change that cannot be reversed. If you tried to heat a thermoset plastic to a high temperature a second time it would simply burn. This characteristic makes thermoset materials poor candidates for recycling.

Why is Polyvinyl Chloride (PVC) used so often?

Rigid PVC in particular has very high density for a plastic making it extremely hard and generally very strong. It is also readily available and very economical which combined with the long-lasting characteristics of most plastics make it an easy choice for many industrial applications like construction.

What Are The Different Types of PVC?

Polyvinyl Chloride is widely available in two broad categories: rigid and flexible.

How is PVC made?

Polyvinyl Chloride is made from one of three emulsion processes:

- Suspension polymerization

- Emulsion polymerization

- Bulk polymerization

Polyvinyl Chloride for Prototype Development on CNC Machines, 3D Printers, & Injection Molding Machines: There are two main issues working with PVC that make it fairly problematic and not generally recommended for use by non-professionals. The first is the emission of toxic and corrosive gases when melting the material. This happens to some extent or another while 3D printing, CNC machining, and injection molding. We recommend you take a look at the MSDS data sheets for different chlorinated hydrocarbon gases like chlorobenzene and discuss the production process with a professional manufacturer. Second is the corrosive nature of PVC. This is problematic when PVC is repeatedly coming into contact with Metal nozzles, cutters, and/or mold tools that are made from a material other than stainless steel or some other similarly corrosion resistant metal.

3D Printing:

Polyvinyl Chloride is available in filament form as a plastic welding rod (the material used for welding) but it is not presently retrofit for specific use in 3D printing. Although there are a growing number of plastics and plastic substitutes available for 3D printing, by far the two most common are still ABS and PLA. At Creative Mechanisms we typically 3D print with ABS. For a list of reasons why and a comparison of the two most common 3D printing plastics (ABS and PLA) for 3D printing read here.

The biggest issue with PVC for 3D printing is its corrosive nature (potentially compromising the functionality of typical machines if it were used over a longer time period). There was an interesting kickstarter to develop a PVC capable 3D printing nozzle (extruder head) put forward by engineer and entrepreneur Ron Steele that unfortunately closed without enough interest in 2014. You can take a look at the introductory pitch (video) here:

CNC Machining:

Polyvinyl Chloride can be cut on a CNC machine but any machinist who has tried has probably experienced degradation in the cutter depending on the material it is made from. PVC is very corrosive and abrasive and cutters that are not made from stainless steel or a comparably corrosive resistant material are likely to deteriorate over time.

Injection Molding:

Polyvinyl Chloride can be injection molded just like other plastics but the inclusion of chlorine in the material complicates the process. This is because melted PVC can give off a corrosive toxic gas. Accordingly, shops need to be equipped with sufficient ventilation systems. Those that aren’t are likely to be hesitant to work with the material. Additionally, special corrosive resistant materials like stainless steel or a chrome plating are required for the mold tool when injection molding PVC plastic. Shrinkage in PVC tends to be between one and two percent but can vary based on a number of factors including material durometer (hardness), gate size, holding pressure, holding time, melt temperature, mold wall thickness, mold temperature, and the Percentage and type of additives.

Is PVC Toxic?

PVC can pose a Health hazard when it is burned as it emits hydrogen chloride (HCl) fumes. In applications where the likelihood of fire is high, PVC free electrical wire insulation is sometimes preferred. Fumes can also be emitted when melting the material (such as during prototyping and manufacturing processes like 3D printing, CNC machining, and injection molding). We recommend you take a look at the Material Safety Data Sheets (MSDS) for different chlorinated hydrocarbon gases like chlorobenzene and discuss the production process with a professional manufacturer.

What are the Advantages of Polyvinyl Chloride?

- Polyvinyl Chloride is readily available and relatively inexpensive.

- Polyvinyl Chloride is very dense and thus very hard and resists impact deformation very well relative to other plastics.

- Polyvinyl Chloride has very good tensile strength.

- Polyvinyl Chloride is very resistant to chemicals and alkalies.

What are the Disadvantages of Polyvinyl Chloride?

- Polyvinyl Chloride has very poor heat stability. For this reason additives which stabilize the material at higher temperatures are typically added to the material during production.

- Polyvinyl Chloride emits toxic fumes when melted and/or subject to a fire.

Although there are some shortcomings, Polyvinyl Chloride is a great material overall. It has a unique blend of qualities that make it particularly useful for the construction business.

Uses

Building and Construction

About three-quarters of all vinyl produced goes into long-lasting building and construction applications. Life-cycle studies show PVC/vinyl is effective in protecting the environment, in terms of low greenhouse gas emissions and conservation of Resources and energy.

Because it is strong and resistant to moisture and abrasion, vinyl is ideal for cladding, windows, roofing, fencing, decking, wallcoverings, and flooring. Vinyl does not corrode like some building materials, does not require frequent painting and can be cleaned with mild cleaning products.

· Siding and Windows

Vinyl helps produce siding and window frames that are extremely durable, affordable, and help conserve energy when heating and cooling homes. In fact, vinyl windows have three times the heat insulation of aluminum windows.

· Wiring and Cables

Vinyl is able to withstand tough conditions behind building walls – such as exposure to changing temperatures and dampness – for the life of the building. As a result, it is one of the most prevalent and trusted materials used in electrical wiring and cables.

· Water Pipes

PVC helps conserve energy and water by creating virtually leak-free pipes that are not prone to corrosion and resist environmental Stress. PVC breakage rates are as low as one percent of the breakage rates of cast metal systems. The lack of build-up in PVC piping improves functionality and increases Energy Efficiency.

Packaging

Because it is durable, dependable and Light weight, flexible PVC helps packaging do its job to maintain the Integrity of the products inside, including medicines. Clear vinyl is used in tamper-resistant over-the-counter medications and shrinkwrap for consumer products. Rigid vinyl film is used in blister and clamshell packaging to protect medicines, personal care products and other household goods.

Healthcare

Vinyl plays a critical safety role in dispensing life-saving medicine through IV bags and medical tubing. The advent of the PVC blood-collection bag was a significant breakthrough because blood bags are flexible and unbreakable, enhancing the development of ambulatory medicine and serving as the foundation for modern blood banks.

Household Products

PVC’s affordability, durability and water resistance make it ideal for rain coats, boots and shower curtains.

,

Polyvinyl chloride (PVC) is a versatile synthetic material that is used in a wide variety of products, including pipes, windows, and flooring. It is the third most widely produced plastic in the world, after polyethylene and polypropylene.

PVC was first synthesized in 1835 by German chemist Eugen Baumann. However, it was not until the early 20th century that PVC began to be produced commercially. The first commercial PVC production plant was opened in Germany in 1912.

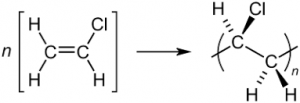

PVC is produced by the polymerization of vinyl chloride monomer (VCM). VCM is a colorless, flammable gas that is produced by the chlorination of ethylene. The polymerization of VCM is a complex process that involves the formation of long chains of vinyl chloride Molecules.

PVC is a versatile material that can be used in a wide variety of applications. It is strong, durable, and resistant to corrosion. PVC is also relatively inexpensive to produce. These properties have made PVC a popular choice for a variety of applications, including:

- Pipes and fittings: PVC is used for a variety of plumbing applications, including water supply lines, sewer lines, and drain lines.

- Windows and doors: PVC is used for the frames and sashes of windows and doors.

- Flooring: PVC is used for both indoor and outdoor flooring.

- Siding: PVC is used for exterior siding on homes and businesses.

- Medical devices: PVC is used in a variety of medical devices, including catheters, blood bags, and surgical gloves.

PVC is a safe material to use when it is properly manufactured and installed. However, there are some potential health concerns associated with PVC. For example, PVC can release dioxins and furans when it is burned. Dioxins and furans are known carcinogens.

PVC can also be recycled. PVC can be recycled into new PVC products or into other products, such as flooring and roofing materials.

The environmental impact of PVC is a complex issue. PVC production does release some pollutants into the environment. However, PVC is a relatively energy-efficient material to produce. PVC is also a durable material that can be recycled.

There are some controversies surrounding PVC. Some people believe that PVC is a dangerous material that should not be used. Others believe that PVC is a safe and useful material that has many benefits.

The future of PVC is uncertain. PVC is a widely used material with many benefits. However, there are some concerns about the environmental impact of PVC. It is possible that PVC will be replaced by other materials in the future.

In conclusion, PVC is a versatile and useful material. However, there are some potential health and environmental concerns associated with PVC. It is important to weigh the benefits and risks of PVC before using it.

What is PVC?

PVC is a versatile material that is used in a wide variety of products, including pipes, windows, and flooring. It is made from polyvinyl chloride, which is a type of plastic.

What are the benefits of PVC?

PVC is a durable and long-lasting material. It is also resistant to corrosion and weathering. PVC is also a relatively inexpensive material.

What are the drawbacks of PVC?

PVC is a non-biodegradable material. It can also release harmful chemicals into the environment when it is burned.

How is PVC made?

PVC is made from polyvinyl chloride, which is a type of plastic. Polyvinyl chloride is made from ethylene and chlorine. These two chemicals are combined to create a polymer, which is then heated and molded into the desired shape.

What are the different types of PVC?

There are two main types of PVC: rigid PVC and flexible PVC. Rigid PVC is used in products such as pipes and windows. Flexible PVC is used in products such as flooring and hoses.

How is PVC recycled?

PVC can be recycled into new products such as pipes, windows, and flooring. It can also be used to make other materials, such as roofing shingles and road signs.

Is PVC safe?

PVC is generally considered to be safe when used as intended. However, there are some concerns about the potential health risks of exposure to PVC chemicals.

What are the environmental impacts of PVC?

PVC is a non-biodegradable material. It can also release harmful chemicals into the environment when it is burned.

What are the alternatives to PVC?

There are a number of alternatives to PVC, including polyethylene, polypropylene, and glass. These materials are all biodegradable and do not release harmful chemicals into the environment.

What is the future of PVC?

The future of PVC is uncertain. Some experts believe that PVC will continue to be used in a variety of products, while others believe that it will be replaced by more sustainable materials.

Sure, here are some MCQs about the topics of polyvinyl chloride (PVC), without mentioning the topic itself:

PVC is a type of:

(A) Thermoplastic

(B) Thermoset

(C) Elastomer

(D) None of the abovePVC is made from the monomer:

(A) Vinyl chloride

(B) Ethylene

(C) Propylene

(D) None of the abovePVC is used to make a variety of products, including:

(A) Pipes and fittings

(B) Windows and doors

(C) Siding and roofing

(D) All of the abovePVC is a relatively safe material, but it can release harmful chemicals when it is burned.

(A) True

(B) FalsePVC can be recycled, but it is not always recycled properly.

(A) True

(B) FalsePVC is a petroleum-based product, and its production contributes to Climate change.

(A) True

(B) FalseThere are a number of alternatives to PVC, including:

(A) Polyethylene

(B) Polypropylene

(C) Polystyrene

(D) All of the aboveAlternatives to PVC are often more expensive than PVC.

(A) True

(B) FalseAlternatives to PVC are often less durable than PVC.

(A) True

(B) FalseAlternatives to PVC are often more difficult to recycle than PVC.

(A) True

(B) False

I hope these MCQs were helpful!