<<–2/”>a >h3>Laboratory method of preparation acetic acid

Ethanoic Acid (Acetic acid – CH COOH)

Ethanoic acid is the second member of the homologous series of carboxylic acids. In other words, vinegar contains about 5 to 8% acetic acid. We will now describe two methods for the manufacture of ethanoic acid. In the first method, ethanoic acid is obtained as a dilute solution called vinegar.

Manufacture of Ethanoic Acid

From Ethanol

Ethanoic acid is manufactured in the form of vinegar by the bacterial oxidation of ethanol. Ethanol is oxidized by the Oxygen of air in the presence of Acetobacter bacteria to form a dilute solution of ethanoic acid called vinegar. In this method, we get ethanoic acid in the form of a dilute solution in water called vinegar. So, we can also say that vinegar is prepared or manufactured by the oxidation of ethanol by air in the presence of Acetobacter bacteria.

From Methanol

Ethanoic acid is manufactured by the reaction between methanol and carbon monoxide in the presence of iridium – rhodium Catalyst. This is a recent commercial method for preparing ethanoic acid.

Properties

- Ethanoic acid is a colourless liquid having a sour taste and a smell of vinegar.

- The boiling point of ethanoic acid is 118° C (391 K)

- When pure ethanoic acid is cooled, it freezes to form a colourless, ice like liquid.

- Ethanoic acid is miscible with water in all proportions.

Chemical Properties

- With Sodium or Sodium Hydroxide

Acetic acid reacts with sodium (or sodium hydroxide) and give sodium acetate.

- With Ammonia

It reacts with ammonia forming ammonium acetate and then on heating, acetamide is got.

iii. With phosphorus pentachloride

It combines with phosphorus pentachloride forming acetyl chloride, phosphorus oxychloride and hydrochloric acid.

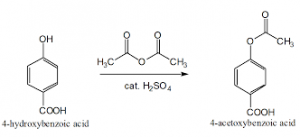

- Esterification

Activity

Take a few drops of acetic acid in a test tube. Add a few drops of ethanol to it. Then add a few drops of concentrated sulphuric acid in a test tube. Warm it in a water bath. Pour these contents in to a beaker containing water. What happens? A fruity odour comes from the beaker. The sweet smell is due to the formation of ester ethyl ethanote.

Acetic acid combines with ethyl alcohol in the presence of concentrated sulphuric acid to give ethyl acetate (which has a fruity odour) and water. It is called esterification and the produce Ethyl acetate is called ester.

- Dehydration

When vapours of acetic acid are passed through phosphorus pentoxide, acetic anhydride is obtained.

- Substitution Reaction

Chlorine reacts with acetic acid in diffused sunlight, in the presence of a catalyst like iron or phosphorus. Hydrogen atoms of CH group in acetic acid are replaced, step-by-step by chlorine atoms, forming monochloro acetic acid, dichloro acetic acid and trichloro acetic acid respectively.

Uses

- It is used for making cellulose acetate which is an important artificial fibre.

- It is used in the manufacture of acetone (propanone) and esters which are used in perfumes.

- Ethanoic acid is used in the preparation of dyes, plastics and drugs.

- Ethanoic acid is used to coagulate rubber from latex.

- Dilute ethanoic acid (in the form of vinegar) is used as a food preservative in the preparation of pickles and sauces.

- It is used for making white lead [2PbCO .Pb(OH) ] which is used as a white paint.

- Ethanoic acid is used as a reagent in chemistry laboratory.

,

Acetic Acid

Acetic acid is a colorless liquid with a sharp, sour taste. It is the main component of vinegar and is used in a variety of industrial and commercial applications. Acetic acid can be prepared in the laboratory by the Fermentation-2/”>Fermentation of ethanol.

Preparation of Acetic Acid

Acetic acid can be prepared in the laboratory by the fermentation of ethanol. The fermentation process is carried out by yeast, which converts ethanol into acetic acid and carbon dioxide. The reaction is as follows:

C2H5OH + O2 CH3COOH + H2O

The fermentation process is carried out in a closed container at a temperature of 30 °C. The ethanol is added to the container and the yeast is added. The container is then sealed and the fermentation process is allowed to proceed for 24 hours. After 24 hours, the acetic acid can be distilled from the mixture.

Distillation of Acetic Acid

The distillation of acetic acid is carried out in a distillation apparatus. The distillation apparatus consists of a condenser, a receiver, a thermometer, a funnel, a beaker, a graduated cylinder, and test tubes. The acetic acid mixture is placed in the beaker and the condenser is attached to the beaker. The receiver is placed below the condenser. The thermometer is inserted into the condenser. The funnel is placed in the top of the condenser. The beaker is heated and the acetic acid vapors are condensed in the condenser. The condensed acetic acid drips into the receiver.

Observations

The acetic acid will be a colorless liquid with a sharp, sour taste. The temperature of the acetic acid will be between 100 °C and 110 °C. The pH of the acetic acid will be between 2 and 3.

Conclusion

Acetic acid can be prepared in the laboratory by the fermentation of ethanol. The acetic acid will be a colorless liquid with a sharp, sour taste. The temperature of the acetic acid will be between 100 °C and 110 °C. The pH of the acetic acid will be between 2 and 3.

Safety Precautions

Acetic acid is a corrosive substance and should be handled with care. It should be stored in a cool, dark place and should be kept out of reach of children. When working with acetic acid, it is important to wear safety glasses and gloves.

Applications of Acetic Acid

Acetic acid is used in a variety of industrial and commercial applications. It is used in the production of vinegar, textiles, plastics, and pharmaceuticals. It is also used as a solvent, a preservative, and a disinfectant.

What is acetic acid?

Acetic acid is a colorless, flammable liquid with a characteristic sour taste and pungent odor. It is the main component of vinegar and is used in a variety of industrial and commercial applications.

How is acetic acid produced?

Acetic acid is produced by fermentation of sugars or starches. The fermentation process is carried out by bacteria called Acetobacter. The bacteria convert the sugars or starches into acetic acid and carbon dioxide.

What are the uses of acetic acid?

Acetic acid is used in a variety of industrial and commercial applications, including:

- Food and beverage production: Acetic acid is used as a preservative in food and beverages. It is also used to make vinegar, which is used as a flavoring agent in many foods.

- Textile manufacturing: Acetic acid is used to make cellulose acetate, which is used in the manufacture of textiles, such as rayon and acetate.

- Leather tanning: Acetic acid is used to tan leather.

- Paper manufacturing: Acetic acid is used to make paper.

- Chemical manufacturing: Acetic acid is used to make a variety of chemicals, including vinyl acetate, acetic anhydride, and acetaldehyde.

What are the safety hazards of acetic acid?

Acetic acid is a corrosive substance that can cause burns to the skin, eyes, and respiratory tract. It is also a flammable liquid that can ignite if it comes into contact with heat or an open flame.

What are the first aid procedures for exposure to acetic acid?

If you are exposed to acetic acid, it is important to seek medical attention immediately. If the acetic acid has come into contact with your skin, wash the area with soap and water for at least 15 minutes. If the acetic acid has come into contact with your eyes, flush them with water for at least 15 minutes and seek medical attention immediately. If the acetic acid has been inhaled, remove the person from the area and provide them with fresh air. Seek medical attention immediately.

What are the storage and disposal requirements for acetic acid?

Acetic acid should be stored in a cool, dry place away from heat and open flames. It should be stored in a tightly sealed container to prevent Evaporation. Acetic acid should be disposed of in accordance with local regulations.

Acetic acid is a colorless liquid that has a characteristic sour taste and pungent odor. It is the main component of vinegar and is used in a variety of industrial and commercial applications.

Acetic acid can be prepared by a number of methods, including:

- Oxidation of ethanol. Ethanol is oxidized to acetic acid by a variety of oxidizing agents, including oxygen, chromic acid, and manganese dioxide.

- Fermentation of sugars. Sugars are fermented by bacteria to produce acetic acid. This is the method used to produce vinegar.

- Synthesis from acetaldehyde. Acetaldehyde is converted to acetic acid by a variety of catalysts, including rhodium, palladium, and platinum.

Question 1

Acetic acid is a:

(A) gas

(B) liquid

(C) solid

(D) none of the above

Answer

(B) Acetic acid is a colorless liquid.

Question 2

Acetic acid has a:

(A) sweet taste

(B) sour taste

(C) bitter taste

(D) salty taste

Answer

(B) Acetic acid has a characteristic sour taste.

Question 3

Acetic acid is the main component of:

(A) vinegar

(B) wine

(C) beer

(D) all of the above

Answer

(A) Acetic acid is the main component of vinegar.

Question 4

Acetic acid can be prepared by:

(A) oxidation of ethanol

(B) fermentation of sugars

(C) synthesis from acetaldehyde

(D) all of the above

Answer

(D) Acetic acid can be prepared by oxidation of ethanol, fermentation of sugars, and synthesis from acetaldehyde.

Question 5

Acetic acid is used in a variety of industrial and commercial applications, including:

(A) production of plastics

(B) production of pharmaceuticals

(C) production of cosmetics

(D) all of the above

Answer

(D) Acetic acid is used in a variety of industrial and commercial applications, including production of plastics, production of pharmaceuticals, and production of cosmetics.